Twinline Laser Line 200

Immediately

Detailed availability

Product description

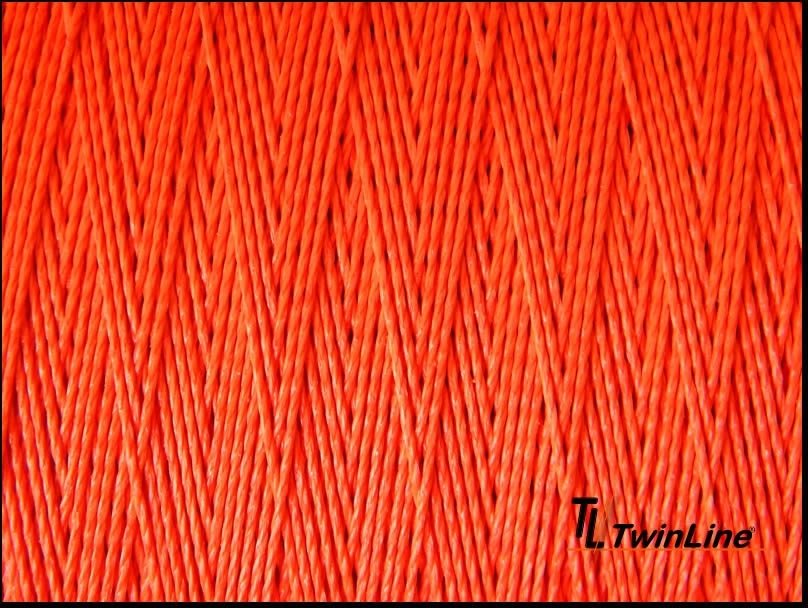

Laser Line 200 Lb. tensile strength - Three stranded twisted torque balanced Kevlar® 49 base with proprietarypolyurethane double coating with a low friction finish impregnated into the cord. This is the ultimate cord for use in extreme conditions.

Current applications include:

- Use in mechanical float assemblies in waste oil tanks.

- Military uses in ocean environments.

- High performance light weight stunt kites.

- Target suspension.

Kevlar is the registered trademark for a para-aramid synthetic fiber, related to other aramids such as Nomex and Technora. Developed at DuPont in 1965, this high strength material was first commercially used in the early 1970s as a replacement for steel in racing tires. Typically it is spun into ropes or fabric sheets that can be used as such or as an ingredient in composite material components.

Currently, Kevlar has many applications, ranging from bicycle tires and racing sails to body armorbecause of its high tensile strength-to-weight ratio; by this measure it is 5 times stronger than steel on an equal weight basis.

Kevlar® 29 (K29)

The original family of product types of Kevlar®, having similar tensile properties with many deniers and finishes. These yarns are used in ballistic applications, ropes and cables, protective apparel such as cut-resistant gloves, in life protection uses such as helmets, vehicular armoring, and plates, and as rubber reinforcement in tires and automotive hoses.

Kevlar® 49 (K49)

High-modulus type used primarily in fiber optic cable, textile processing, plastic reinforcement, ropes, cables, and composites for marine sporting goods and aerospace applications.

Kevlar® brand fiber has provided a lightweight, flexible and dimensionally stable means of strengthening ropes and cables used across several industries, from mountaineering ropes and fishing lines to electro-mechanical cables and fine gauge cables for electronic device applications such as mobile phone cables, computer power cords, USB cords, and MP3 ear phone cables..

Its resistance to chemicals and temperature extremes make it an ideal component for ropes and cables under severe loads in harsh environments.

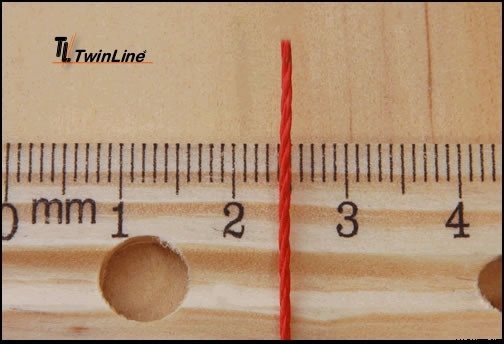

Thickness

0.9 mm

Weight

0,03 kg(The product may have a light retail packaging.)

Country of origin

CommentsAdd a comment

Brand

reviews

reviews