Sports» Cycling» Tyres» Tubeless accessories» Sealant»

Peaty's Holeshot Tubeless Sealant 500ml

Availability

This product is not for sale at the moment.

Detailed availability

Product description

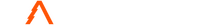

Developed alongside World Cup mechanics and world champion racers. Peaty’s improved Holeshot Tubeless Sealant is packed full of biodegradable fibres & sealing particles to give a fast and strong seal. Using the latest fast-acting latex, the water-based sealant is ammonia-free, non-hazardous and lasts up to 6 months in the tyre in temperate climates. It won’t ball up in the tyre and is easily washed out. Peaty's biodegradable fibres and particles bind together with the fast-acting latex to create a clot (like platelets in your blood) to quickly & effectively seal holes and tears up to 6mm.

Biofibres tangle up with particles and latex to create a faster, more durable seal. Peaty's original sealant didn’t have any fibres. This is because the most common - and easiest - way of achieving a fast seal is by using microplastic fibres. These are very cheap and easy to get hold of, but they’re terrible for the environment, so Peaty's stayed away from them. It’s taken years to find a biodegradable fibre that seals holes well, yet also lasts a long time in the tyre. To get a good seal you need fibres of a really specific size, so after years of testing and development Peaty's has finally found a fibre which gives incredible sealing performance, while remaining super durable.

Thinner Formulation for a Faster Tubeless Setup

Peaty's has also made the sealant slightly thinner, for easier initial setup, and added higher concentrations of sealing compounds - to work with the fibres and platelets and give a better / more durable seal. Perfecting a sealant which flows easily, seals quickly, works in a good range of operating temperatures and remains super durable has been a long and arduous journey. But Peaty's has finally got there!

Black Platelets - Less Mess

The shiny turquoise bits Peaty's had in their original sealant formula can look a bit of a mess. However, the original size, shape and material of Peaty's sealant platelets always performed the best. So they simply changed them to be black to blend in with tyre carcasses and look far less messy if it gets sprayed everywhere.

Wait, is that plastic glitter?!

Hell no! No micro-plastics or microfibres here… The platelets in Peaty's sealant are BioGlitter made from a special form of cellulose from hardwoods, primarily eucalyptus sourced from responsibly managed and certified plantations operating to PEFC™ www.pefc.org standards. They work like platelets in your blood, building up behind holes to help our fast acting sealant form an even stronger bond with the rubber in your tyre.

Setup instructions

Peaty's top sealing tips

Weight

0,558 kg(Includes the weight of the packaging)

Capacity

500 milliliters

CommentsAdd a comment

Brand

This product is not for sale at the moment.

Detailed availability

Product description

Developed alongside World Cup mechanics and world champion racers. Peaty’s improved Holeshot Tubeless Sealant is packed full of biodegradable fibres & sealing particles to give a fast and strong seal. Using the latest fast-acting latex, the water-based sealant is ammonia-free, non-hazardous and lasts up to 6 months in the tyre in temperate climates. It won’t ball up in the tyre and is easily washed out. Peaty's biodegradable fibres and particles bind together with the fast-acting latex to create a clot (like platelets in your blood) to quickly & effectively seal holes and tears up to 6mm.

- Biodegradable sealing fibres

- Biodegradable platelets

- C02 compatible

- Seals up to 6mm holes

- Operating pressures: 15 to 120 psi

- Operating temperature: -20°c to +50°c

- Seals porous tyres and bead/rim gaps

Biofibres tangle up with particles and latex to create a faster, more durable seal. Peaty's original sealant didn’t have any fibres. This is because the most common - and easiest - way of achieving a fast seal is by using microplastic fibres. These are very cheap and easy to get hold of, but they’re terrible for the environment, so Peaty's stayed away from them. It’s taken years to find a biodegradable fibre that seals holes well, yet also lasts a long time in the tyre. To get a good seal you need fibres of a really specific size, so after years of testing and development Peaty's has finally found a fibre which gives incredible sealing performance, while remaining super durable.

Thinner Formulation for a Faster Tubeless Setup

Peaty's has also made the sealant slightly thinner, for easier initial setup, and added higher concentrations of sealing compounds - to work with the fibres and platelets and give a better / more durable seal. Perfecting a sealant which flows easily, seals quickly, works in a good range of operating temperatures and remains super durable has been a long and arduous journey. But Peaty's has finally got there!

Black Platelets - Less Mess

The shiny turquoise bits Peaty's had in their original sealant formula can look a bit of a mess. However, the original size, shape and material of Peaty's sealant platelets always performed the best. So they simply changed them to be black to blend in with tyre carcasses and look far less messy if it gets sprayed everywhere.

Wait, is that plastic glitter?!

Hell no! No micro-plastics or microfibres here… The platelets in Peaty's sealant are BioGlitter made from a special form of cellulose from hardwoods, primarily eucalyptus sourced from responsibly managed and certified plantations operating to PEFC™ www.pefc.org standards. They work like platelets in your blood, building up behind holes to help our fast acting sealant form an even stronger bond with the rubber in your tyre.

Setup instructions

Peaty's top sealing tips

The approximate size of the packed product or the sales package is 80 x 240 x 80 mm.

Weight

0,558 kg(Includes the weight of the packaging)

Capacity

500 milliliters

CommentsAdd a comment

Brand

Steve Peat Explains - Peaty's Holeshot Biofibre Sealant 👑

How to Setup Tubeless Tyres - 3. Sealant

reviews

reviews